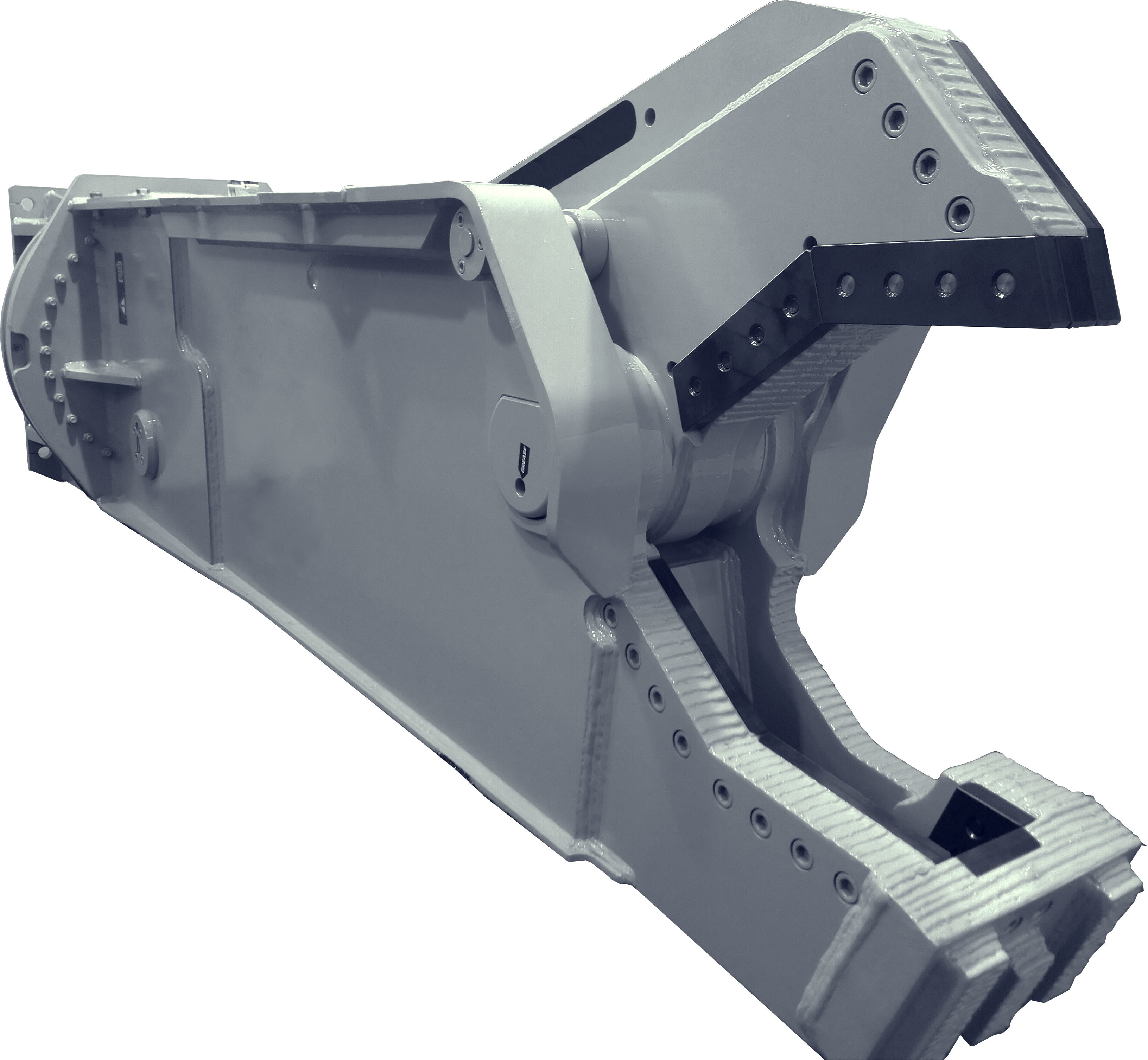

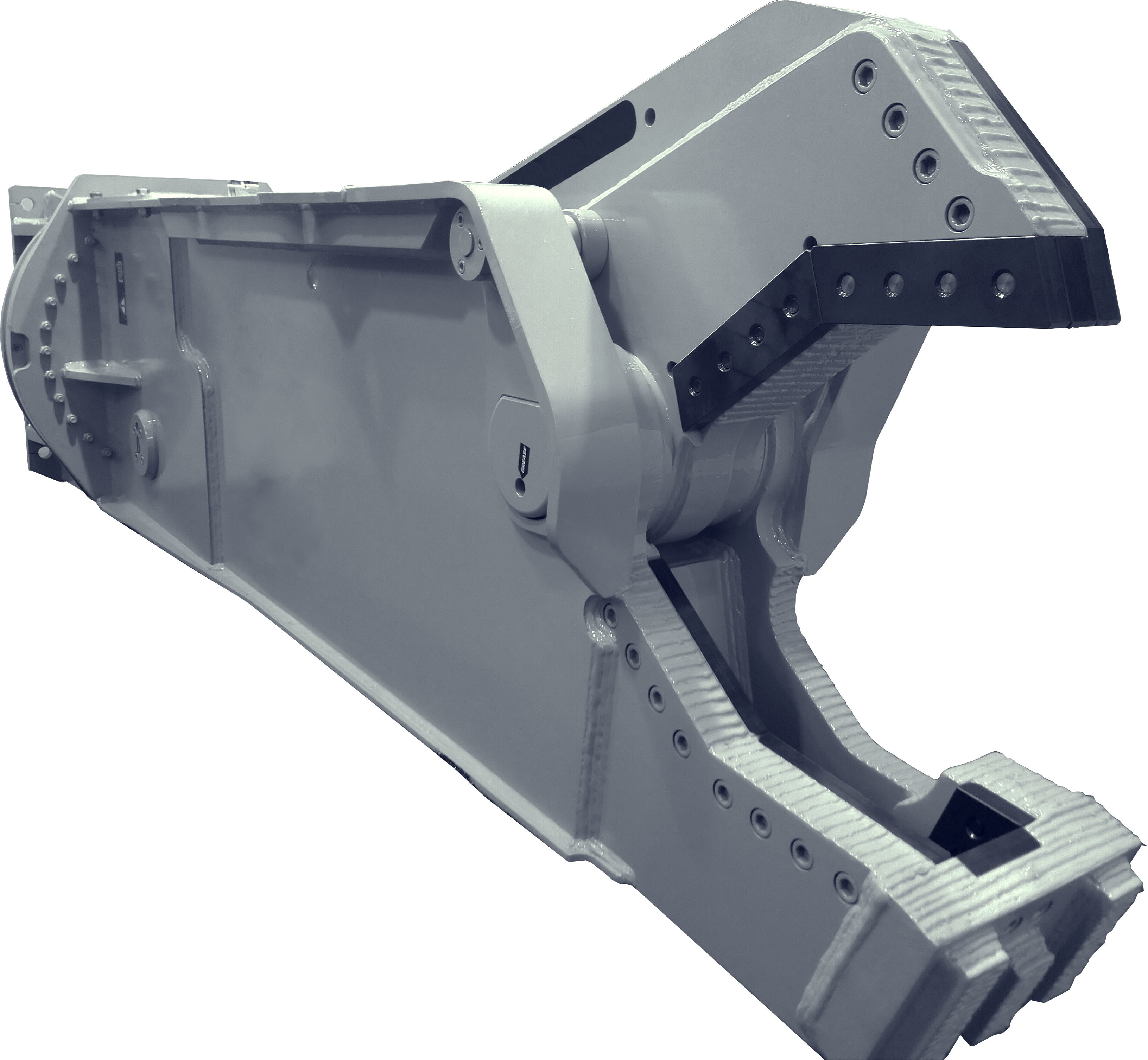

Scrap shear Yellow S 100 (90 … 120 t) 9950 kg

The Green Attachments Yellow S Scrap shear range has been designed for metal cutting in recycling area. The kinematics of Yellow line scrap shears makes sure that maximum power is reached just in the right moment. There must be enough force to start cutting and also in the end of movement in order to cut sheet metals. The jaw geometry of Yellow S scrap shears and the blade configuration assure a clean linear cut of the scrap metal.

S scrap shears / mobile shears have been designed for demolishing iron structures and for cutting different structural steels,as pipes, sheets and iron cases. The innovative design and the wear resistant steels used assure big cutting force and convenient weight.

Scrap shears are designed with flange which allows the customer to change adapter easily. Green Attachments provides different adapters when needed.

The S hydraulic mobile scrap shear range consists of eleven models for 7 - 130 tonne excavators (15 000 – 287 000 lb).

Applications of Yellow S scrap shears

- Recycling job in scrap yard

- Demolition of steel structures

- Tire cutting

- Special applications

Features of Yellow S scrap shears:

- Wear resistant Hardox 400 has been used to decrease wearing. It is essential to build all parts which touch the material by wear resistant material.

- Yellow S Scrap shears / mobile shears have been designed to heavy duty applications by optimising its robust structure.

- Long cutting blades allows cutting of big beams, optimum kinematics pull steel deep to monster’s throat and then cutting is easy.

- Yellow S Scrap shears have a high speed valve to increase performance. Then oil is rotated from rod side to piston side regeneratively, all products has not that feature.

- Wear resistant cutting blades are bolt mounted and easily reversible. This means less down time and better productivity. It has the best possible productivity when blades are sharp. Material of blades is special wear resistant high quality steel, immune for small wear and tear.

- Four way indexing guide blades of mobile shear

- Bolt on piercing tips

- A system for blades precise alignment also in conditions when ”scissor-effect” tries to turn moving jaw sidewards. Yellow S Scrap shears have adjustable cushions for precise and reliable movement.

- Axels are hardened and greasing points has been designed to make maintenance easy.

- Heavy-Duty pivot pin of dedicated mobile shear for strength and durability

- Scrap shears have easily changeable steel bushings and they have been over sized in order to increase life time.

- Slew bearing of scrap shears has a double roll desing (bigger models) to increase strength.

- Hydraulic rotation makes positioning of scrap shears easy. Scrap shears are also used for sorting of material, then rotation is essential.

- Durable orbital hydraulic motors with a planetary gear in order to maximise power and productivity.

- Hydralic motors are equipped with double pressure relief valves

- Scrap shears have easily removeable maintenance covers to decrease service time

- Big cylinders ensure huge power and they are reversed in order to protect cylinder rod.

- Scrap shears have well designed hydraulics to minimize overheating.

- Scrap shears have maintenance free SAE fittings in order to minimize leaks and problems.

Scrap shear specs

| Weight |

|

kg / lb |

9950 / 21990 |

| Excavator weight |

|

t /1000 lb |

90 - 120 / 200 - 265 |

| Opening |

|

mm / Inch |

920 / 36.2 |

| Length |

|

mm / Inch |

5000 / 197 |

| Max cutting force |

|

t /1000 lb |

1300 / 2860 |

| Cutting force (tip) |

|

t /1000 lb |

270 / 594 |

| Working pressure |

|

bar / psi |

340 / 4960 |

| Excavator oil flow |

|

l/min / gpm |

800 / 213 |

| Rotation pressure max |

|

bar / psi |

100 / 1460 |

| Rotation oil flow max |

|

l/min / gpm |

60 / 16 |

Video

https://youtu.be/4TBWTdlrJYs

https://youtu.be/MlzJWb7thmg

https://youtu.be/tpl8yWR1UVE S06 Kouvola

https://youtu.be/z8qrA38KTMA S06 Kouvola 2 tire cutting

https://youtu.be/o2XLyKDoip4 Yellow S06 Kouvola 3 valve recycling