Demolition and Sorting Grapple Yellow G 03 (4…8 t) 250 kg

Yellow line demolition and sorting grapples have been designed for demolition and recycling applications when demolition grapples are installed in the place of excavator’s bucket. Design of demolition grapples has been completed according to customer’s needs in order to acquire light but robust structure and powerful and efficient prodcutivity. Due to demolition grapples' robust structure it is well built for primary demolition of targets made of brick or wood. Grapples can manage other materials as well. Recycling applications require strickt and efficient separating which is easily managed by grabs. Typical application is recycling plant and there Yellow G grapples are used to downsize and load the material fast and efficient due to its fully rotatable structure for easy manouverability. Long reach applications are also typical due to light structure of a Yellow G grapple.

Demolition and sorting grapples are available with or without rotation. Without rotation the grapple is suitable for rotating tilt installation. Green attachments recommend our rotation always when the application is demolition or other demanding heavy duty job. Grapples are designed with flange which allows the customer to change adapter easily. Green Attachments provides different adapters when needed.

The range consists of nine models and many jaw options for 2.5 - 65 tonne excavators (5 500 – 143 300 lb).

Applications of Demolition and Sorting Grapple

- demolition af buildings

- high reach applications

- sorting and recycling

- stone handling

and many more

Features of Yellow G demolition and recycling grapple:

- Wear resistant Hardox 400 has been used to decrease wearing. It is essential to build all parts which touch the material by wear resistant material. Info

- Frame of a grapple is optimized to have the structure wide enough. Then jaws are supported by bearings of axels and it gives more life time.

- Axels are hardened and greasing points has been designed to make maintenance easy.

- Selector grabs have changeable steel bushings and they have been over sized in order to increase life time. Info

- Slew bearings have double roll desing (bigger grapples) to increase strength. Info

- Wear resistant edge plates are bolt mounted and easily reversible.Info

- Hydraulic rotation makes handling of material easy especially in recycling phase adter demolition. Durable orbital hydraulic motors have a gear in order to maximise power and productivity. Info

- Hydralic motors are equipped with double pressure relief valves Info

- Sorting and demolition grapples have easily removeable maintenance covers to decrease service time Info

- Big demolition grapples have double hydraulic motors as option Info

- Syncronising of jaws have been carried out by syncronizing bar. They enable reliability and allow strickt movement.

- Big cylinders ensure huge power, needed especially in demolition applications. Info

- Cylinders are equipped with pressure relief valves to increase safety.

- Demolition grapples have well designed hydraulics to minimize overheating.

Jaw options:

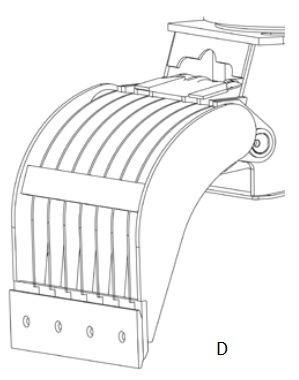

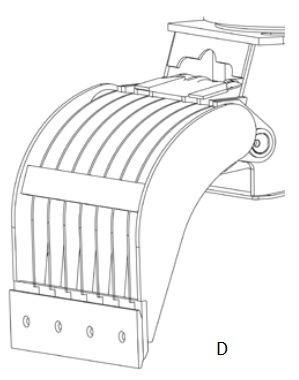

D jaws for demolition. Demolition and recycling grapple with D jaws is suitable for demolition application. Rib model jaws allows a driver more easily see the target.

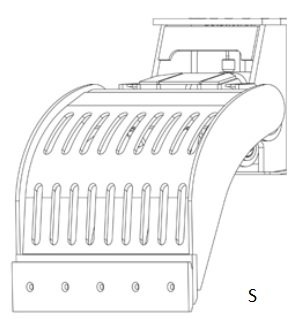

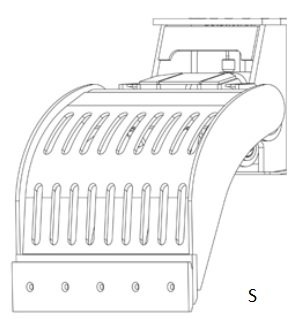

S jaws for sorting. Demolition and sorting grapples with plate reinforced S jaws is designed for recycling applications. Loose material does not stick between ribs so easily. Jaws are very strong and suitable also for demolition applications.

Demolition and Sorting Grapple specs

.jpg)

| Weight |

kg / lb |

250 / 550 |

| Excavator weight |

t /1000 lb |

4 - 8 / 8.8 - 18 |

| Opening |

mm / Inch |

1100 / 43.3 |

| Width |

mm / Inch |

500 / 19.7 |

| Working pressure |

bar / psi |

200 / 2920 |

| Excavator oil flow |

l/min / gpm |

20 / 290 |

| Rotation pressure max |

bar / psi |

80 / 1170 |

| Rotation oil flow max |

l/min / gpm |

20 / 5 |

| Closing Force |

kN |

20 |

Youtube video

.jpg)