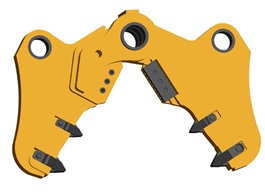

Multi-processor Yellow M 80 C (80 … 100 t) 7800 kg

Green Attachments Yellow M multi-processor range has been designed as a versatile, multi-function tool for all applications by using a universal body attaching a variety of interchangeable jaws. Those multi-processor jaws are suitable for the demolition of reinforced concrete structures, steel structure cutting, concrete pulverising, tank demolition and many more. Also typical application for multi-processor is for mounting on long reach demolition booms.

The multi-processors geometry makes sure that maximum power is reached just in the right moment and two cylinder kinematics allows very high power also in the end of the movement when high cutting force is needed. Robust structure of multi-processors with fast and powerful performance allows efficient demolition, the most typical are reinforced concrete structures. There are cutting blades in order to cut reinforcements. Yellow M multi-processor´s design has been made according to customer’s needs to acquire light and durable structure combined with high power and efficienfy.

Multi-processors are flange mounted design which allows the customer to change adapter easily. Green Attachments provides different adapters when needed.

The range consists of eleven models for 4 - 130 tonne excavators (8 800 – 290 000 lb).

Applications of combi shears

- demolition

- long reach applications

- concrete crushing

- pulverising

- recycling

- steel cutting

- tank cutting

Features of Yellow M combi shears

- Easily interchangeable jaws are key element of combi shears. Only one universal body is needed, you can have multi-purpose tool by changing jaws

- Wear resistant steel has been used to decrease wearing. It is essential to build all parts which touch the material by wear resistant material.

- Yellow M multi-processors have a high speed valve to increase performance. Then oil is rotated from rod side to piston side regeneratively, all products has not that feature.

- Teeth are made of special forged material. They are easily replaceable

- Wear resistant cutting blades are bolt mounted and easily reversible.

- Axels are hardened and greasing points has been designed to make maintenance easy.

- Multi-processors have changeable steel bushings and they have been over sized in order to increase life time.

- Slew bearing has double roll desing (bigger models) to increase strength.

- Hydraulic rotation makes positioning of cutter-crushes easy. Durable orbital hydraulic motors have a gear in order to maximise power and productivity.

- Hydraulic motors are equipped with double pressure relief valves

- Multi-processors have easily removeable maintenance covers to decrease service time

- Big cylinders ensure huge power and they are reversed in order to protect cylinder rod.

- Multi-processors have well designed hydraulics to minimize overheating.

Jaws of combi cutters: C jaws

C Crusher jaws are designed for primary crushing. They have short cutting blades for cutting of reinforced iron and easily changeable teeth for concrete crushing.

Specs of Yellow M combi shears

| Weight |

|

kg / lb |

7800 / 17 200 |

| Excavator weight |

|

t /1000 lb |

80 - 100 / 180 - 220 |

| Opening |

|

mm / Inch |

1700 / 66.9 |

| Length |

|

mm / Inch |

3200 / 126 |

| Max cutting force |

|

t /1000 lb |

720 / 1590 |

| Crushing force (tip) |

|

t /1000 lb |

190 / 420 |

| Working pressure |

|

bar / psi |

340 / 4960 |

| Excavator oil flow |

|

l/min / gpm |

500 / 133 |

| Rotation pressure max |

|

bar / psi |

100 / 1460 |

| Rotation oil flow max |

|

l/min / gpm |

60 / 16 |

Videos of Yellow M combi shears

https://youtu.be/3HZzDumPeJA Yellow M features